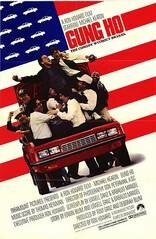

It's like a Bizarro-world "Gung Ho"!

It's like a Bizarro-world "Gung Ho"!

Over at the Harvard Business Review, blogger Dick Nolan (Boeing Philip M. Condit Professor of Business Administration at the UW's Foster School of Business) thinks Boeing's Trojan Horse moment was in outsourcing that famed Boeing know-how. Writes Nolan, "Before the 787, Boeing had retained almost total control of airplane design and provided suppliers precise engineering drawings for building parts (called 'build to print')."

Not that that has changed entirely--ironically enough, here's this recent headline from the Wall Street Journal: "Boeing takes control of plant." But that's a South Carolina plant. For the 787, Boeing has constructed 300-partner supply chain that spans the globe.

Continues Nolan:

Boeing effectively gave Tier 1 suppliers a large part of its proprietary manual, "How to Build a Commercial Airplane," a book that its aeronautical engineers have been writing over the last 50 years or so. Instead of "build to print," Boeing provided suppliers with performance specifications for parts and components and collaboratively worked with them in the design and manufacturing of major components such as the wing, fuselage section, and wing box.

The only problem is that once Boeing has trained and retooled its far-flung suppliers, it will have planted a worldwide crop of competitors. China, Nolan thinks, is the most likely to run with the commercial airplane ball. Airbus has already agreed to a Chinese final-assembly plant, work that it, like Boeing, has tried to keep "stateside."

So forget South Carolina: Asia's lower-paid workforce is learning from the best how to build a plane from nose to tail, and how to put it together and sell it for about fifteen percent less (per Nolan) than Airbus or Boeing. It's a fait accompli, a matter of when, not if.

Jilted Snohomish County Executive Aaron Reardon says, "The decision has been reached." The Seattlepi.com has a few more Boeing details, but the long and the short of it is that Boeing did what everyone expected them to do. The second 787 Dreamliner assembly line will be sited in North Charleston, S.C. Local TV station WYFF 4 is reporting that it will bring 12,000 jobs to the area. Yesterday South Carolina legislators approved a significant welcome basket of tax breaks and incentives, contingent on Boeing investing $750 million into the area over the next seven years.

Most Recent Comments