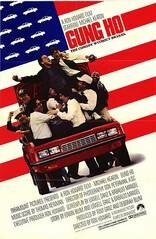

It's like a Bizarro-world "Gung Ho"!

It's like a Bizarro-world "Gung Ho"!

Over at the Harvard Business Review, blogger Dick Nolan (Boeing Philip M. Condit Professor of Business Administration at the UW's Foster School of Business) thinks Boeing's Trojan Horse moment was in outsourcing that famed Boeing know-how. Writes Nolan, "Before the 787, Boeing had retained almost total control of airplane design and provided suppliers precise engineering drawings for building parts (called 'build to print')."

Not that that has changed entirely--ironically enough, here's this recent headline from the Wall Street Journal: "Boeing takes control of plant." But that's a South Carolina plant. For the 787, Boeing has constructed 300-partner supply chain that spans the globe.

Continues Nolan:

Boeing effectively gave Tier 1 suppliers a large part of its proprietary manual, "How to Build a Commercial Airplane," a book that its aeronautical engineers have been writing over the last 50 years or so. Instead of "build to print," Boeing provided suppliers with performance specifications for parts and components and collaboratively worked with them in the design and manufacturing of major components such as the wing, fuselage section, and wing box.

The only problem is that once Boeing has trained and retooled its far-flung suppliers, it will have planted a worldwide crop of competitors. China, Nolan thinks, is the most likely to run with the commercial airplane ball. Airbus has already agreed to a Chinese final-assembly plant, work that it, like Boeing, has tried to keep "stateside."

So forget South Carolina: Asia's lower-paid workforce is learning from the best how to build a plane from nose to tail, and how to put it together and sell it for about fifteen percent less (per Nolan) than Airbus or Boeing. It's a fait accompli, a matter of when, not if.

As of 10 a.m. this morning, you can take light rail from downtown to the SeaTac Airport in 36 scenic minutes. There's enough space under most seats to stow baggage if you're holding carry-on in your lap. The fare is $2.50 one-way. Here's a photo gallery of our preview trip. (In other transit news, everyone wants a piece of the First Hill streetcar.)

On December 15, 2009, at 10:27 a.m., Boeing's 787 Dreamliner lifted off at Paine Field for a test flight. For three hours, it flew back and forth over the Sound, until increasingly rainy weather called a halt to the flight. Testing will continue for about nine months, and involve three 787s and about a dozen flight crew. Even Ryanair's brinksmanship on its huge 737 order couldn't dampen Boeing spirits.

Other local bidness: Weyerhauser announced it's becoming a real estate investment trust, McDonald's double-dog-dared Starbucks to provide free Wi-Fi, and the Seattle Times triumphed temporarily over death (taxes).

Seattle left last week's record low temperatures behind, and started focusing on eating outside. The Mobile Chowdown will return to Interbay on January 9. City Hall and SDOT are making street-food-friendly noises regarding regulatory changes in 2010, including making it easier for vendors to set up on the outskirts of city parks. We also mistakenly pumped 10 million gallons of sewage into Elliott Bay.

Sports fans had an early Christmas, discovering Husky QB Jake Locker, pitcher Cliff Lee, and hothead Milton Bradley under their tree.

Most Recent Comments