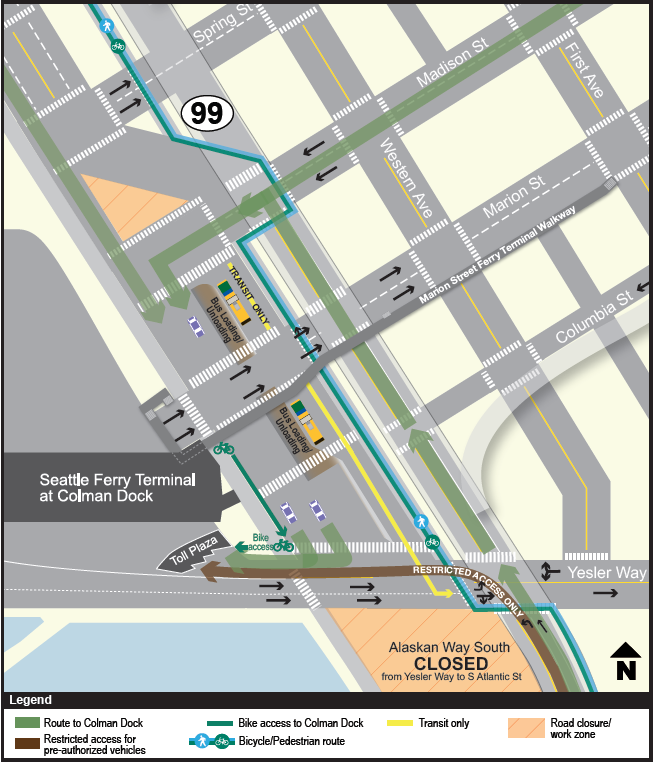

Moving ahead with the Alaskan Way Viaduct Replacement project, Washington Department of Transportation crews will reroute Alaskan Way traffic south of Spring Street to a newly improved road below the viaduct. That in turn will change the way you get to the ferry toll plaza at Colman Dock. On the bright side, you have until 2014 to get used to the new arrangement, so it should sink in eventually. Study the graphic to the right carefully (or download this PDF: Ferry-Detail-Handout). There will be a pop quiz, probably during rush hour.

For you bus riders, please note that the bus stop for Metro routes 16 and 66 is moving to a new bus island in front of the ferry terminal. That’s right, you get a whole island! Pour us out a mai tai.

Specifically, making this shift will allow WSDOT to expand its tunnel staging area north to Yesler Way, and let them get the area ready for the world’s largest tunnel boring machine (a “57.5-foot-diameter, $80-million drill”), set to begin its work in 2013. There’s no way construction on this scale won’t be disruptive, but officials say they are trying their best to keep traffic flowing.

The Washington State Department of Transportation and the Seattle Department of Transportation are rerouting existing roads along the waterfront and in Pioneer Square, and implementing strategies to keep traffic moving while maintaining access to businesses in those neighborhoods, including:

- Allowing drivers to use Yesler Way to exit the ferry terminal

- Increasing the width of Alaskan Way between Yesler Way and Spring Street to accommodate ferry holding lanes

- Adding more than 60 temporary on-street parking spaces on Alaskan Way between Spring and Pike streets

To try some POV-preparation, watch this video that WDOT has put together for you, which features huge, levitating street signs that are unfortunately not available in real life.